In 2009, the Cristallerie de Saint Paul initiated its diversification. This new orientation required big investments for the manufacturing as well as for the R&D part.

The company has now 9 employees divided as follows:

- Administrative and commercial part 2 persons

- Manufacturing 5 persons working in shifts of 8 hours

- Quality control laboratory and R&D 2 persons

MANUFACTURING

In order to meet your needs as best as we can, we have three tilting furnaces, two of which are used for the manufacturing of large volumes (batch of 250 kg) and the third one, with a lower capacity, enables us to finalize the development of new compositions (batch of 30 kg). For the development of high purity glasses, we have set up a new pot furnace; this tool guarantees a production perfectly refined and exempt from batch stone.

Our total capacity for the melting part is around 250 T/year.

These glasses can also be sold in the form of powders with various particle sizes. Thanks to different grinding technologies, we can develop powders from a few microns to several hundreds of microns.

YOUR QUALITY REQUIREMENTS

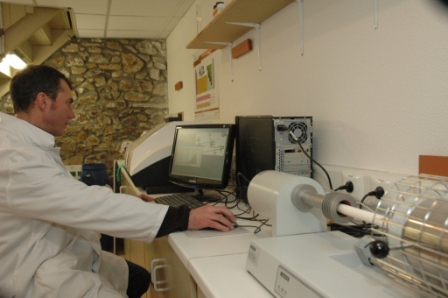

In order to guarantee the constant quality of our products, we carry out the most thorough controls. That is why we have in our laboratories the most sophisticated tools :

Laser granulometer, atomic absorption spectrophotometer,

PH meter, conductimeter, dilatometer,

Colorimeter, centrifuge, co-precipitation reactor,

viscometer, tunnel furnace, box furnace.

These characterization tools also enable us to work very hard on the R&D in various fields.

Our reactivity, our adaptability and our technical competences are our main assets on the market of specialty glasses; we are available and attentive to all your future needs in terms of R&D for the development of your future products.

Syndicat Professionnel des Émailleurs Français 12 avenue Garibaldi 87000 Limoges 06 80 93 85 88

AFPI Limousin "CAP Emailleur d'Art sur Métaux"

9 rue Jean-Baptiste Say

PA Magré-Romanet

87000 Limoges

+ 33 5 55 30 08 08

[email protected]

www.afpilimousin.fr